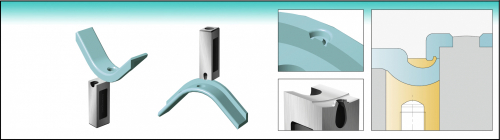

Standard version S1

with machining allowance

STANDARD S1

Version S1 - with machining allowance

- with machining allowance on upper surface

- slight contourings possible

- same properties as version S2

- available in round (TGR) and square (TGS) versions

Ready to use!

Tunnel gate inserts version S1 can be installed directly. You drill the hole - we supply the proper tunnel gate insert.

Gate point area S1

The gate point diameter of tunnel gate inserts "Standard" is already completely constructed. Due to the special manufacturing method all gate point diameters from 0,6 to 2,8 are clearly reproducible.

Sizes / shot weights

The chart shows the shot weights which can be reached with the respective sizes depending on the viscosity of the plastic materials used.

| TGR 6 | TGR / TGS 8 | TGR / TGS 10 | TGR / TGS 12 | TGR / TGS 14 | |

|---|---|---|---|---|---|

| Name | TGR 6 | TGR / TGS 8 | TGR / TGS 10 | TGR / TGS 12 | TGR / TGS 14 |

| Anschnitt | 0.6 | 0.6 / 0.8 | 0.8 / 1.2 / 1.6 | 1.2 / 1.6 / 2.0 | 1.6 / 2.0 / 2.4 / 2.8 |

| Ø Kanal | 2.5 | 3 | 4 | 5 | 6 |

| NV* | 3 | 5 | 30 | 50 | 200 |

| MV* | 2 | 4 | 20 | 35 | 120 |

| HV* | 1 | 3 | 12 | 25 | 75 |

* max. shot weight (g) | NV: low viscosity | MV: medium viscosity | HV: high viscosity

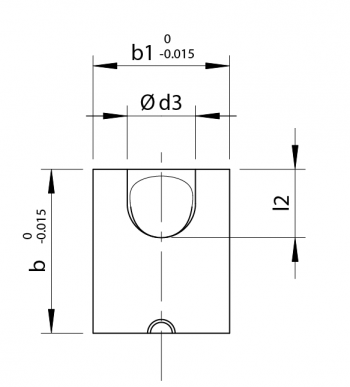

TGS

| Name | b | b1 | d1 | d3 | h | h1 | h2 | l1 | l2 | M | Version | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TGS8 | TGS8 | 8 | 6 | 0.6 / 0.8 | 3 | 22.6 | 0.6 | 1.7 | 13 | 3.25 | 4 | S1 |

| TGS10 | TGS10 | 10 | 8 | 0.8 / 1.2 / 1.6 | 4 | 22.0 | 0.8 | 2.0 | 12 | 4 | 5 | S1 |

| TGS12 | TGS12 | 12 | 10 | 1.2 / 1.6 / 2.0 | 5 | 22.8 | 0.8 | 2.2 | 11 | 5 | 5 | S1 |

| TGS14 | TGS14 | 14 | 12 | 1.6 / 2.0 / 2.4 / 2.8 | 6 | 22.8 | 0.8 | 2.4 | 10 | 6 | 6 | S1 |

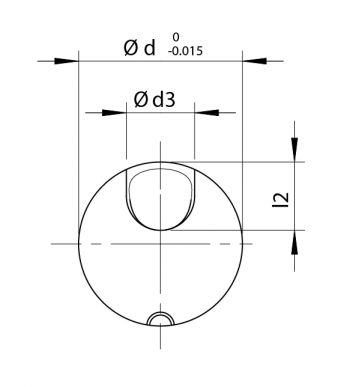

TGR

| Name | b | d1 | d3 | h | h1 | h2 | l1 | l2 | M | Version | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| TGR6 | TGR6 | 6 | 0.6 | 2.5 | 17.6 | 0.6 | 1.4 | 10 | 2.5 | 4 | S1 |

| TGR8 | TGR8 | 8 | 0.6 / 0.8 | 3 | 22.6 | 0.6 | 1.7 | 13 | 3.25 | 4 | S1 |

| TGR10 | TGR10 | 10 | 0.8 / 1.2 / 1.6 | 4 | 22.8 | 0.8 | 2.0 | 15 | 4 | 5 | S1 |

| TGR12 | TGR12 | 12 | 1.2 / 1.6 / 2.0 | 5 | 22.8 | 0.8 | 2.2 | 11 | 5 | 5 | S1 |

| TGR14 | TGR14 | 14 | 1.6 / 2.0 / 2.4 / 2.8 | 6 | 22.8 | 0.8 | 2.4 | 10 | 6 | 6 | S1 |

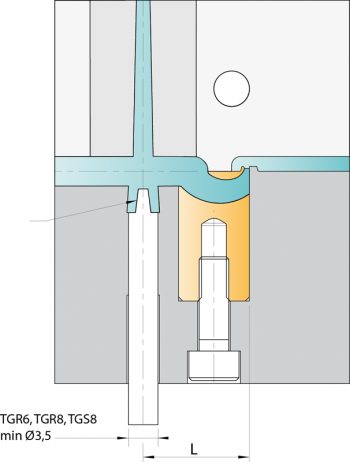

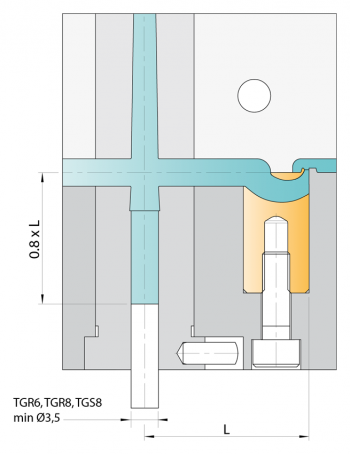

Distance to ejector

- Low shore hardness = shorter distance L

- Use centring pin

- Max. hardness 100 Shore A

Table for distance L

| Name | TPE, TPU etc. | PE, PP, PET etc. | PC/ABS, PA, POM, HI-PC etc. | PA+GF, PC, SAN, PMMA etc. | |

|---|---|---|---|---|---|

| TGR 6 | TGR 6 | 9-12 | 12-18 | 15-22 | 18-25 |

| TGR/TGS 8 | TGR/TGS 8 | 11-14 | 15-22 | 19-27 | 23-30 |

| TGR/TGS 10 | TGR/TGS 10 | 15-18 | 19-27 | 24-33 | 28-36 |

| TGR/TGS 12 | TGR/TGS 12 | 18-22 | 22-30 | 27-36 | 32-40 |

| TGR/TGS 14 | TGR/TGS 14 | 20-25 | 25-33 | 30-37 | 35-43 |

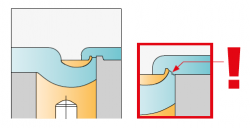

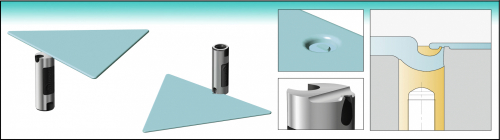

Companion vestige

For optimum degating (especially of flat parts), we recommend the use of a companion vestige supplementing the vestige with cutting edge. This configuration will ensure that the part is separated from the runner flush with the parting line. Users will find this particularly advantageous in cases where materials are susceptible to stringing.

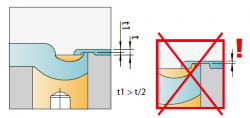

Flat parts

If the molded part is very thin, the vestige must be ground down. (t1>t/2)

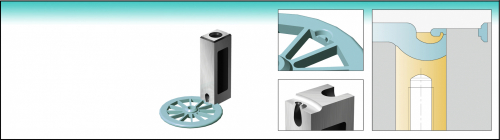

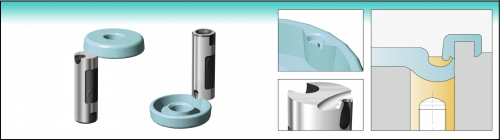

Examples of installation

rounded edge

with flow promoter

rounded separation

flat, with companion vestige

Further documents

Your contact persons for this product are: