OUR PRODUCTS FORM YOUR VISION - WITH PERFECTION.

MADE BY I-MOLD

WELCOME AT I-MOLD

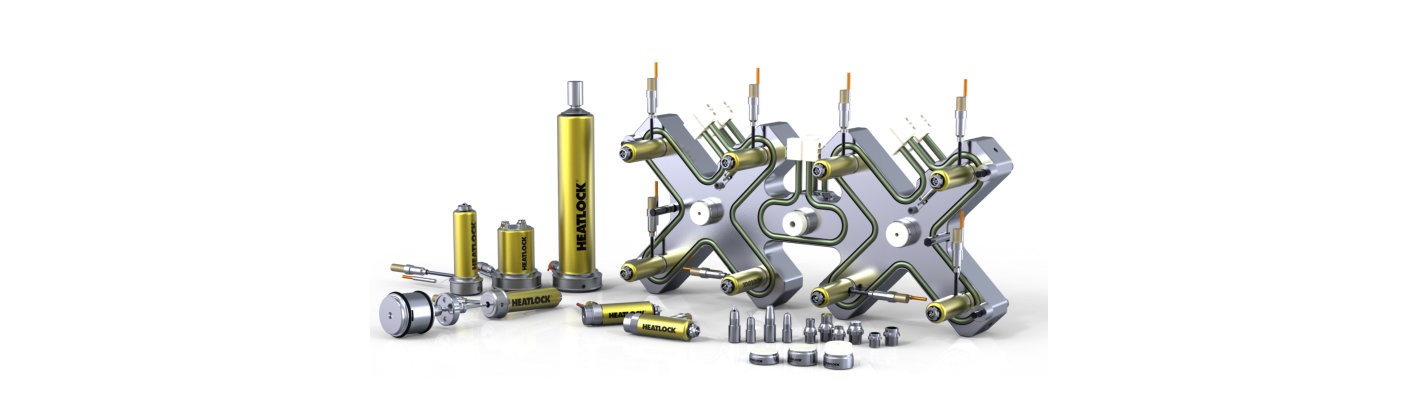

Innovative product range in the field of injection moulding technology

The challenges of our customers spur us on. In the search for the ideal solution, we rely on constructive questioning and meet complexity with creativity.

We are technicians. Not suppliers, but reliable partners. Not service providers, but enthusiastic experts. And our innovations shape the world.