Side gating

Curved tunnel permits gating deep inside the part

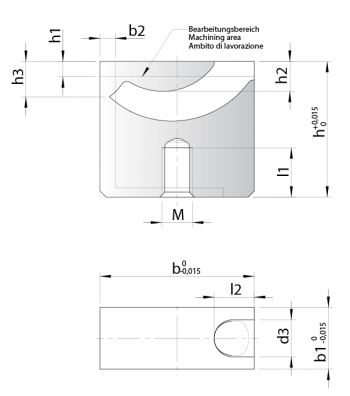

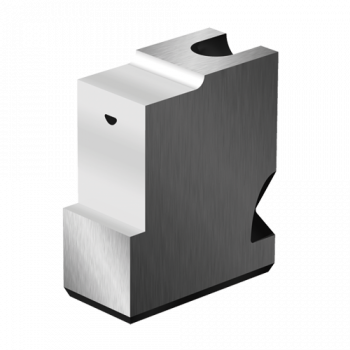

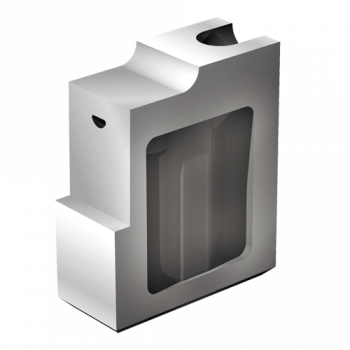

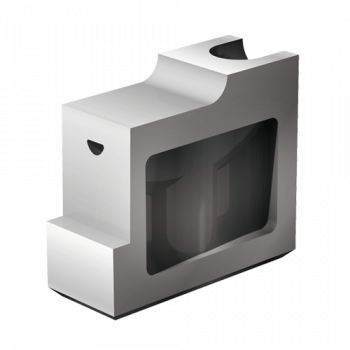

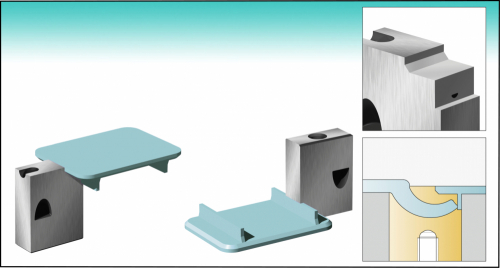

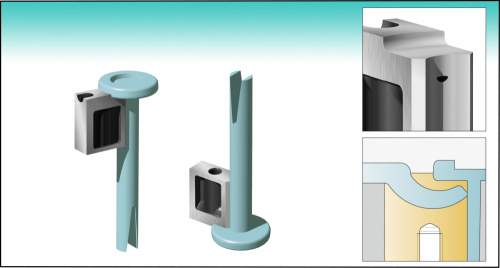

SIDE GATING SGC

Gate insert with side gating - SGC

- curved tunnel permits gating deep inside the part

- integrated dead-end recess reduces loss of pressure and shear stress

- highly wear-resistant hot working steel M2 (1.3343) – 54+2 HRC

side gating SGC

Sizes / Shot weights

The chart shows the shot weights which can be reached with the respective sizes depending on the viscosity of the plastic materials used.

| SGC-XS | SGC-S | SGC-1 | SGC-2 | SGC-3 | |

|---|---|---|---|---|---|

| Name | SGC-XS | SGC-S | SGC-1 | SGC-2 | SGC-3 |

| Anschnitt | 0.4 - 0.8 | 0.4 - 1.0 | 0.6 - 1.4 | 0.8 - 2.1 | ~ Ø 1.1 - 3.3 |

| Ø Kanal | 2.5 | 2.5 | 4 | 6 | 8 |

| NV* | 12 | 20 | 35 | 250 | 1000 |

| MV* | 7 | 12 | 25 | 120 | 500 |

| HV* | 5 | 8 | 15 | 90 | 300 |

* max. shot weights (g) | NV: low viscosity | MV: medium viscosity | HV: high viscosity

side gating SGC

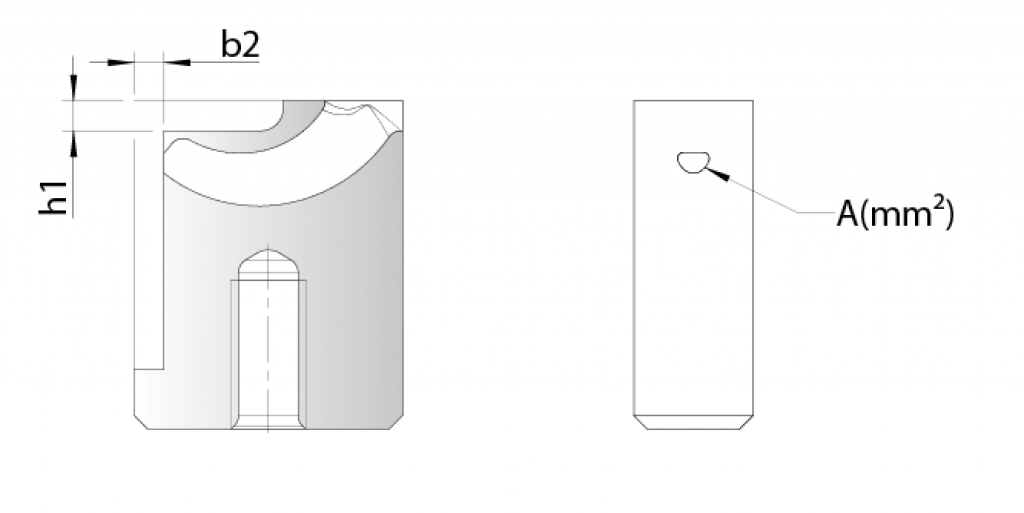

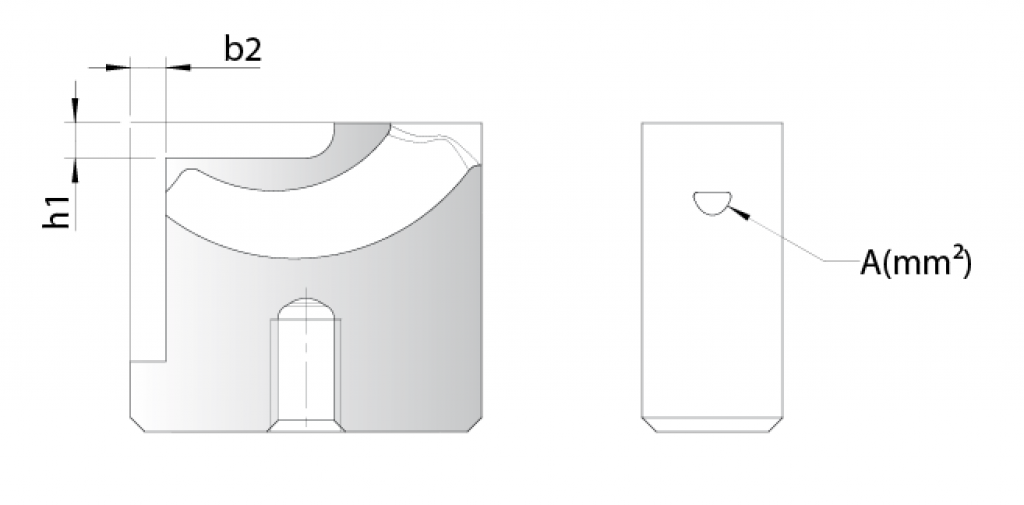

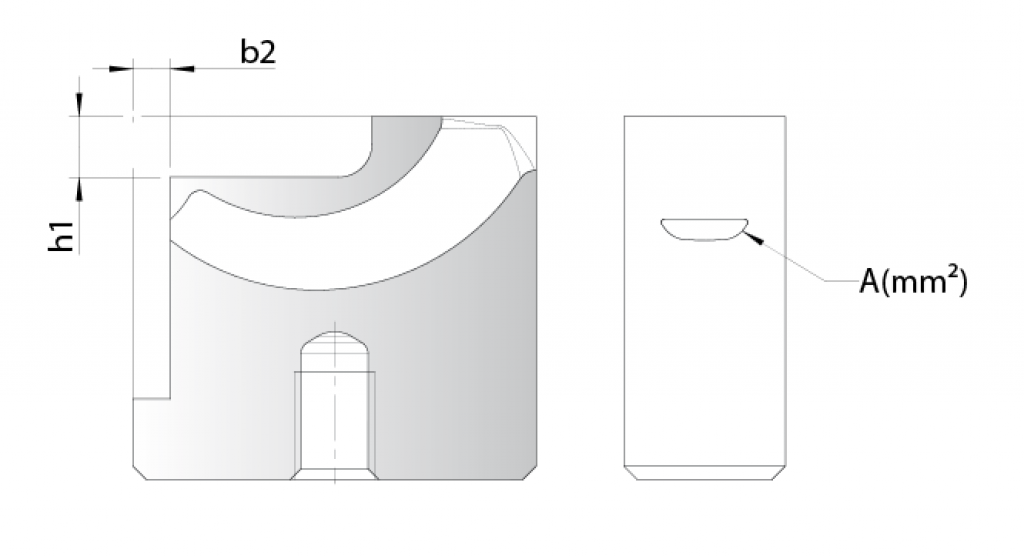

Details

| Name | b | b1 | b2 max. | d3 | h | h1 max. | h2 | h3 | l1 | l2 | M | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SGC-XS | SGC-XS | 10 | 5 | 1.1 | 2.5 | 12 | 0-6 | 1.9 | 2.0 | 5 | 3.2 | 4 |

| SGC-S | SGC-S | 15 | 6 | 2.0 | 2.5 | 18 | 2 | 3.5 | 4.0 | 8 | 4 | 4 |

| SGC-1 | SGC-1 | 18 | 8 | 1.8 | 4 | 22 | 2 | 3.5 | 4.1 | 9 | 5.2 | 5 |

| SGC-2 | SGC-2 | 25 | 10 | 2.5 | 6 | 22 | 2.5 | 4.8 | 5.7 | 8 | 6.5 | 5 |

| SGC-3 | SGC-3 | 30 | 12 | 2.8 | 8 | 27 | 4.5 | 7.5 | 8.4 | 9 | 7 | 6 |

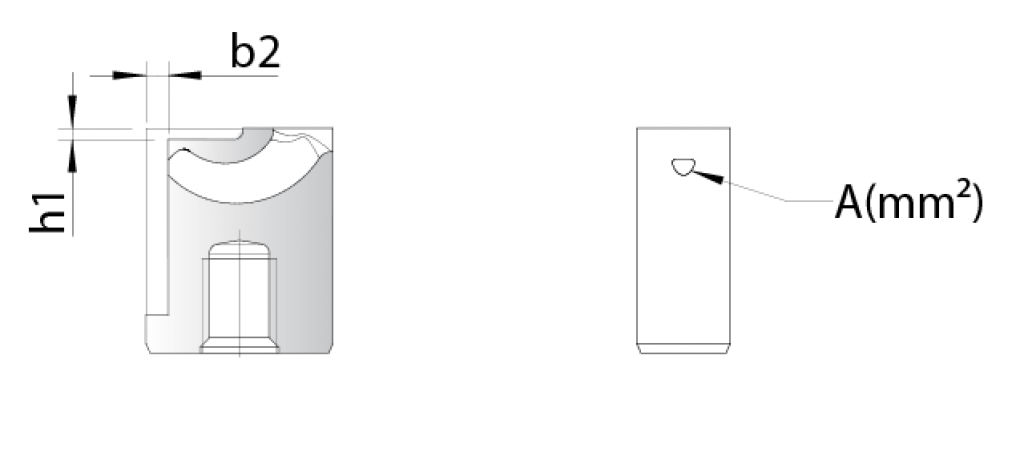

side gating SGC

SGC-XS

| A [mm²] | ~ Ø [mm] | b2 [mm] | |

|---|---|---|---|

| 1 | 0.13 | 0.4 | 0.9 |

| 2 | 0.3 | 0.6 | 1.0 |

| 3 | 0.53 | 0.8 | 1.1 |

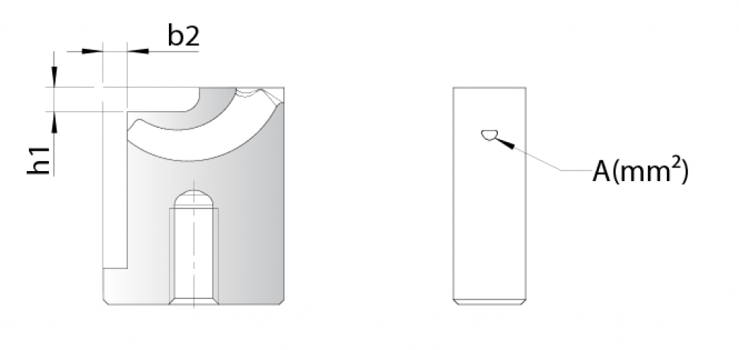

side gating SGC

SGC-S

| A [mm²] | ~ Ø [mm] | b2 [mm] | |

|---|---|---|---|

| 1 | 0.15 | 0.4 | 1.7 |

| 2 | 0.33 | 0.6 | 1.8 |

| 3 | 0.55 | 0.8 | 1.9 |

| 4 | 0.79 | 1.0 | 2.0 |

side gating SGC

SGC-1

| A [mm²] | ~ Ø [mm] | b2 [mm] | |

|---|---|---|---|

| 1 | 0.28 | 0.6 | 1.4 |

| 2 | 0.53 | 0.8 | 1.5 |

| 3 | 0.82 | 1-0 | 1.6 |

| 4 | 1.15 | 1.2 | 1.7 |

| 5 | 1.52 | 1.4 | 1.8 |

side gating SGC

SGC-2

| A [mm²] | ~ Ø [mm] | b2 [mm] | |

|---|---|---|---|

| 1 | 0.28 | 0.6 | 1.7 |

| 2 | 0.54 | 0.8 | 1.8 |

| 3 | 0.84 | 1-0 | 1.9 |

| 4 | 1.2 | 1.2 | 2.0 |

| 5 | 1.57 | 1.4 | 2.1 |

| 6 | 2.0 | 1.6 | 2.2 |

| 7 | 2.43 | 1.75 | 2.3 |

| 8 | 2.9 | 1.9 | 2.4 |

| 9 | 3.4 | 2.1 | 2.5 |

side gating SGC

SGC-3

| A [mm²] | ~ Ø [mm] | b2 [mm] | |

|---|---|---|---|

| 1 | 1.0 | 1.1 | 2.0 |

| 2 | 1.75 | 1.5 | 2.1 |

| 3 | 2.56 | 1.8 | 2.2 |

| 4 | 3.43 | 2.1 | 2.3 |

| 5 | 4.35 | 2.35 | 2.4 |

| 6 | 5.32 | 2.6 | 2.5 |

| 7 | 6.33 | 2.85 | 2.6 |

| 8 | 7.38 | 3.0 | 2.7 |

| 9 | 8.48 | 3.3 | 2.8 |

side gating SGC

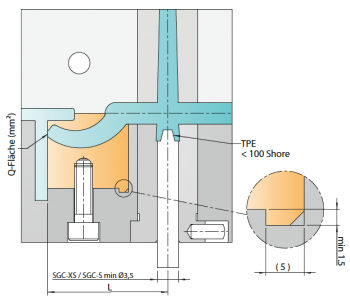

Distance to ejector

- Low Shore hardness = shorter distance L

- Use centring pin

- Max. hardness 100 Shore A

Table for distance L

| TPE, TPU etc. | PE, PP, PET etc. | PC/ABS, PA, POM, HI-PC etc. | PA+GF, PC, SAN, PMMA etc. | ||

|---|---|---|---|---|---|

| SGC-XS | SGC-XS | 12-16 | 13-20 | 16-23 | 22-29 |

| SGC-S | SGC-S | 16-21 | 18-25 | 21-28 | 27-34 |

| SGC-1 | SGC-1 | 21-26 | 26-34 | 31-39 | 36-45 |

| SGC-2 | SGC-2 | 28-33 | 31-39 | 36-44 | 41-50 |

| SGC-3 | SGC-3 | 33-38 | 38-48 | 43-53 | 48-58 |

side gating SGC

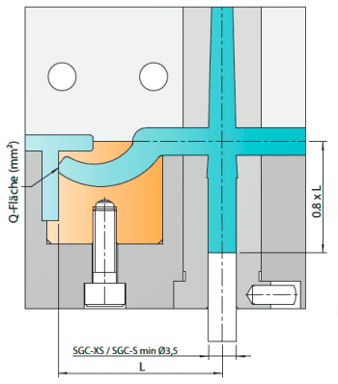

Examples of installation

Side gating - standard installation

Side gating - adapted to part

Downloads

Further documents

Your contact persons for this product are: