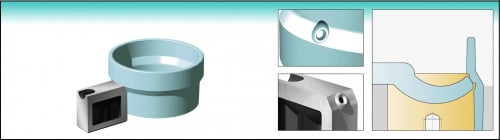

TGC - konturierbar

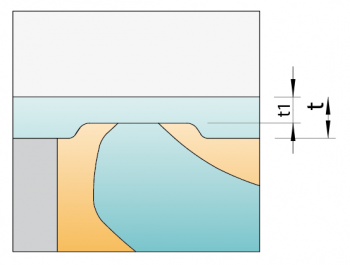

für Konturierungen bis zu 10 mm - individuell anpassbar

TGC

Konturierbar TGC

- Für Konturierungen bis zu 10mm

- Individuell anpassbar

- In 2 Härteklassen (60 HRC / 40 HRC) erhältlich

TGC

Größen / Schussgewichte

Die abgebildete Tabelle zeigt die mit den jeweiligen Größen erreichbaren Schussgewichte in Abhängigkeit zur Viskosität der verwendeten Kunststoffe.

| TGC-XS | TGC-S | TGC-1 | TGC-2 | TGC-3 | TGC-4 | |

|---|---|---|---|---|---|---|

| Name | TGC-XS | TGC-S | TGC-1 | TGC-2 | TGC-3 | TGC-4 |

| max. Konturtiefe | 1 | 2 | 2 | 3 | 5 | 10 |

| Anschnitt | 0.4 - 0.6 | 0.4 - 0.8 | 0.6 - 1.2 | 0.8 - 1.8 | 0.5x4.5 - 1.5x5.5 | 0.5x4.5 - 1.5x5.5 |

| Ø Kanal | 2.5 | 2.5 | 4 | 6 | 8 | 8 |

| NV* | 5 | 12 | 35 | 120 | 1000 | 1000 |

| MV* | 4 | 7 | 25 | 75 | 500 | 500 |

| HV* | 3 | 5 | 15 | 50 | 300 | 300 |

* max. Schussgewichte (g) | NV: niedrige Viskosität | MV: mittlere Viskosität | HV: hohe Viskosität

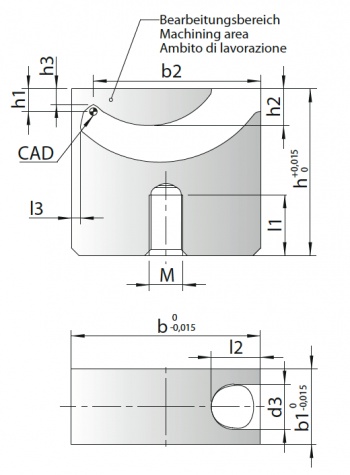

TGC

TGC

| Name | b | b1 | b2 | d3 | h | h1 | h3 | l1 | l2 | l3 | M | HRC | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TGC-XS | TGC-XS | 10 | 5 | 8.5 | 2.5 | 12 | 1 | 0.6 | 5 | 3.2 | 0.7 | 4 |

Version U = 40 HRC |

| TGC-S | TGC-S | 15 | 6 | 12.3 | 2.5 | 18 | 2 | 1.5 | 8 | 4 | 0.9 | 4 |

Version U = 40 HRC |

| TGC-1 | TGC-1 | 18 | 8 | 16 | 4 | 22 | 2 | 1.3 | 9 | 5.2 | 0.9 | 5 |

Version U = 40 HRC |

| TGC-2 | TGC-2 | 25 | 10 | 22.1 | 6 | 22 | 3 | 2.1 | 8 | 6.5 | 1.2 | 5 |

Version U = 40 HRC |

| TGC-3 | TGC-3 | 30 | 12 | 26.9 | 8 | 27 | 5 | 4.1 | 9 | 7 | 1.2 | 6 |

Version U = 40 HRC |

| TGC-4 | TGC-4 | 45 | 12 | 41.2 | 8 | 36 | 10 | 9.1 | 8 | 9.6 | 1.8 | 6 |

Version U = 40 HRC |

TGC

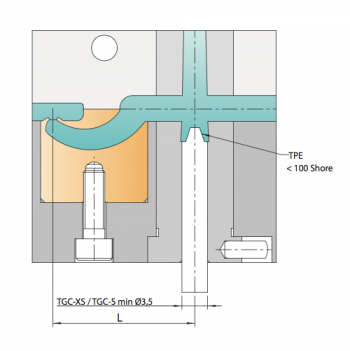

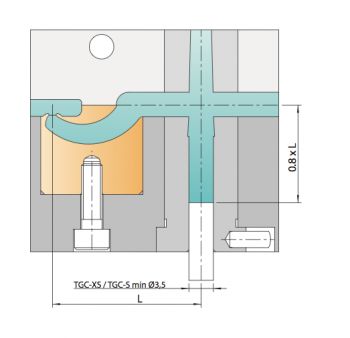

Abstand zum Auswerfer

- Kleine Shorehärte = geringes Abstandsmaß L

- Zentrierzapfen verwenden

- Shorehärte max. 100 Shore A

Diagramm für Abstandsmaß L

| Name | TPE, TPU etc. | PE, PP, PET etc. | PC/ABS, PA, POM, HI-PC etc. | PA+GF, PC, SAN, PMMA etc. | |

|---|---|---|---|---|---|

| TGC-XS | TGC-XS | 12-16 | 13-20 | 16-23 | 22-29 |

| TGC-S | TGC-S | 16-21 | 18-25 | 21-28 | 27-34 |

| TGC-1 | TGC-1 | 21-26 | 26-34 | 31-39 | 36-45 |

| TGC-2 | TGC-2 | 28-33 | 31-39 | 36-44 | 41-50 |

| TGC-3 | TGC-3 | 33-38 | 38-48 | 43-53 | 48-58 |

| TGC-4 | TGC-4 | 48-53 | 53-63 | 58-68 | ? |

TGC

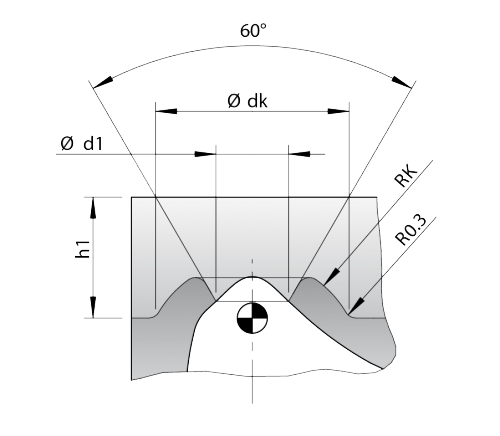

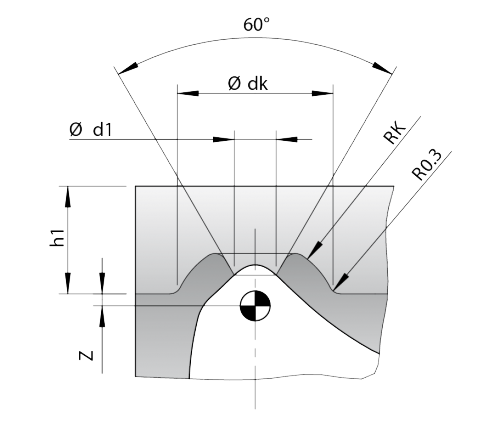

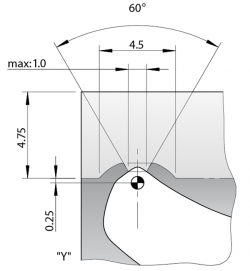

Kalotten - TGC-XS / -S / -1 / -2

Standard-Kalotte

Kleine Kalotte

| Anguss Konturierbar TGC - XS Kalotten | Name | Kalotte | h1 | d1 max | dk | Rk | Z |

|---|---|---|---|---|---|---|---|

| TGC-XS | TGC-XS | Standard | 1.0 | 0.6 | 2.5 | 1.6 | - |

| TGC-S | TGC-S | Standard | 2.0 | 0.8 | 2.7 | 1.7 | - |

| TGC-1 | TGC-1 | klein | 1.8 | 0.7 | 2.6 | 1.4 | 0.2 |

| TGC-1 | TGC-1 | Standard | 2.0 | 1.2 | 3.2 | 1.8 | - |

| TGC-2 | TGC-2 | klein | 2.75 | 1.2 | 3.5 | 2.0 | 0.25 |

| TGC-2 | TGC-2 | Standard | 3.0 | 1.8 | 4.5 | 2.6 | - |

TGC

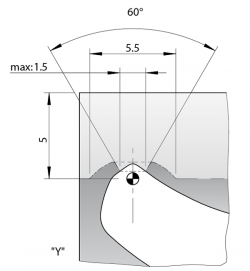

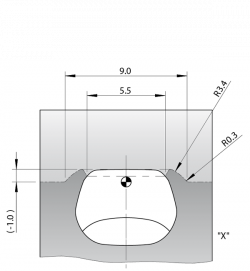

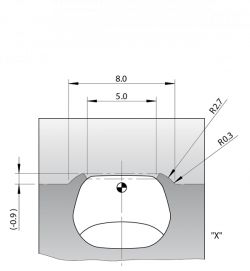

Kalotten - TGC-3 / -4

Standard-Kalotte

Kleine Kalotte

TGC

Kalotten-Varianten

Kugelförmige Kalotte mit Kegel

Abgeflachte Kalotte mit Kegel

Abgeflachte Kalotte ohne Kegel

TGC

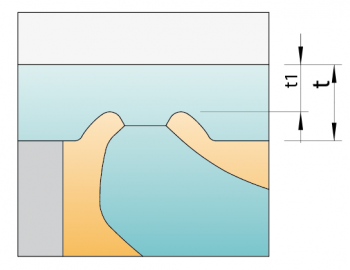

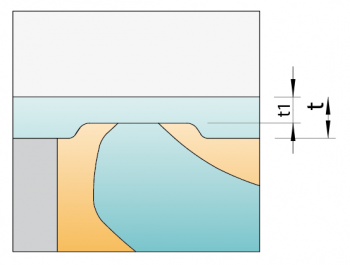

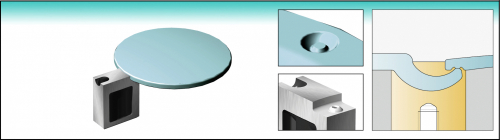

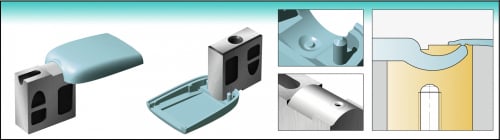

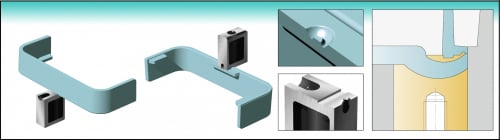

Einbaubeispiele

unter Flächen

unter gewölbter Fläche

halbierter Anspritzpunkt

Anspritzung auf Schräge

Downloads

Weiterführende Unterlagen

Ihre Ansprechpartner zu diesem Produkt sind: